Product Description

We are a professional company in bulk material handling, transportation, storage, processing, accessory equipment design, integration and manufacturing. We can provide a complete set of solutions. Thank you for reading the information and welcome to purchase! Welcome to agent distribution!

Brief introduction of the company’s manufacturing capacity

The company’s headquarters, technology and sales are located in Lingang New Area of China (ZheJiang ) pilot free trade zone,The company’s manufacture base is located in Xihu (West Lake) Dis. county, ZHangZhoug Province, which is known as “the most beautiful county in China”. It is 65 kilometers away from HangZhou city and 60 kilometers away from Qiandao Lake. The transportation to Xihu (West Lake) Dis. county from other places is very convenient. No matter by railway, highway or waterway. The manufacture base has a total plant area of around 30000 square CHINAMFG and workshop is equipped with more than 300 sets of various advance manufacture equipment, including 20 sets of CNC precision vertical lathe MODEL: SMVTM12000×50/150, CNC vertical lathe MODEL:DVT8000×30/32, CNC horizontal lathe, MODEL: CK61315×125/32, CNC horizontal lathe MODEL:CK61200×80/32, CNC Grounding boring and milling machine MODEL:TJK6920,etc.Most of the parts are machined by using CNC machine equipment. Theis is a hot treatment CHINAMFG with size 10.5m×8m×8m. The manufacture base also equipped with lifting capacity of 25t, 50t, 100t, 200t overhead crane to handle heavy workpiece and assembly work.

Metalworking equipment

| Name of equipment | Model number | Quantity | SCOPE of application | |

| A | Lathes | |||

| 1 | Vertical Lathe | Numerical control | 1 | Φ 12000 |

| 2 | Vertical Lathe | Numerical control | 1 | Φ 8000 |

| 3 | Vertical Lathe | 1 | Φ 1600 | |

| 4 | Vertical Lathe | C5112A | 1 | Ф 1250 |

| 5 | Horizontal Lathe | Numerical control | 1 | CK61315×12×100T |

| 6 | Horizontal Lathe | CW61200 | 1 | Ф 2000×8000 |

| 7 | Horizontal Lathe | CW61160 | 1 | Ф 1600×6500 |

| 8 | Horizontal Lathe | CW6180 | 2 | Ф 800×3000 |

| 9 | Horizontal Lathe | CW61125 | 2 | Ф 1250×5000 |

| 10 | Horizontal Lathe (remodel) | CW62500 | 2 | Ф 2800×6000 |

| 11 | Common Lathe | CY6140 | 3 | Ф 400×1000 |

| 12 | Common Lathe | CA6140 | 3 | Ф 400×1500 |

| 13 | Common Lathe | C620 | 2 | Ф 400×1400 |

| 14 | Common Lathe | C616 | 1 | Ф 320×1000 |

| 15 | Common Lathe | C650 | 1 | Ф 650×2000 |

| B | Drilling machine | |||

| 1 | Radial drilling machine | Z3080 | 3 | Ф 80×2500 |

| 2 | Radial drilling machine | Z3040 | 2 | Ф 60×1600 |

| 3 | Universal drilling machine | ZW3725 | 3 | Ф 25×880 |

| C | Planing machine | |||

| 1 | Shaper | B665 | 1 | L650 |

| 2 | Hydraulic Shaper | B690 | 1 | L900 |

| 3 | Gantry Planer | HD–16 | 1 | L10000×B1600 |

| D | Milling Machine | |||

| 1 | 4 Coordinate Milling Machine | Numerical control | 1 | 2500×4000 |

| 2 | Gantry milling machine | Numerical contro | 1 | 16mx5mx3m |

| 3 | Gantry milling machine | Numerical contro | 1 | 12mx4mx2.5m |

| 4 | Gantry milling and boring machine | Numerical contro | 1 | Φ 250 |

| 5 | Vertical Milling Machine | XS5054 | 1 | 1600×400 |

| 6 | Horizontal Milling Machine | C62W | 1 | 1250×320 |

| 7 | Horizontal Milling Machine | X60 | 1 | 800×200 |

| 8 | Gantry milling machine | X2014J | 1 | L4000×B1400 |

| 9 | Gantry milling machine | X2571J | 1 | L3000×B1000 |

| 10 | Floor end milling | TX32-1 | 1 | L1500×H800 |

| E | Grinding machine | |||

| 1 | External Grinder | M131W | 1 | Ф 300×1000 |

| 2 | External Grinder | M1432B | 1 | Ф 320×15000 |

| 3 | Surface Grinder | M7130 | 1 | L 1000×300 |

| 4 | Tool grinder | M6571C | 1 | Ф 250 |

| F | Boring machine | |||

| 1 | Floor-standing milling and boring machine | TJK6920 | 1 | X12000 × Y4500 × Z1000 |

| 2 | Boring machine | TSPX619 | 1 | Ф 1000 |

| 3 | Boring machine | T616 | 1 | Ф 800 |

| 4 | Boring machine | T611 | 1 | Ф 800 |

| G | Slotted bed | |||

| 1 | Slotted bed | B5032 | 1 | H320 |

| H | Other machine tools | |||

| 1 | Gear hobbing machine | Y3150 | 1 | Ф 500 M=6 |

| 2 | Hacksaw machine | G7571 | 1 | Ф 220 |

Products and services available

Material handling equipment

Storage equipment

Conveying equipment

Feeding equipment

Component of conveying system

Belt conveyor parts

Large and medium sized finishing parts

If you need above products, please contact us!

ZheJiang Sunshine Industrial Technology Co. , Ltd.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car, Customization |

|---|---|

| Hardness: | Customization |

| Gear Position: | Customization |

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do you choose the right type of plastic material for specific applications?

Choosing the right type of plastic material for specific applications requires careful consideration of various factors. Here’s a detailed explanation of the process:

1. Identify Application Requirements: Begin by understanding the specific requirements of the application. Consider factors such as temperature range, chemical exposure, mechanical stress, electrical properties, dimensional stability, and regulatory compliance. This initial assessment will help narrow down the suitable plastic material options.

2. Research Plastic Material Properties: Conduct thorough research on different types of plastic materials and their properties. Consider factors such as mechanical strength, thermal stability, chemical resistance, electrical conductivity, impact resistance, UV stability, and food safety approvals. Plastic material datasheets and technical resources from manufacturers can provide valuable information.

3. Evaluate Material Compatibility: Assess the compatibility of the plastic material with the surrounding environment and other components in the system. Consider the potential for chemical reactions, galvanic corrosion, thermal expansion, and any specific requirements for mating surfaces or interfaces. Ensure the selected material is compatible with the intended operating conditions.

4. Consider Manufacturing Process: Evaluate the manufacturing process involved in producing the desired component or product. Different plastic materials may have specific requirements or limitations for processes such as injection molding, extrusion, blow molding, or machining. Ensure the chosen material is compatible with the selected manufacturing method and can meet the desired quality and production efficiency.

5. Assess Cost and Availability: Consider the cost and availability of the plastic material. Some specialty or high-performance plastics may be more expensive or have limited availability compared to more common materials. Evaluate the cost-effectiveness and feasibility of using the selected material within the project’s budget and timeline.

6. Consult with Material Experts: If necessary, consult with material experts, engineers, or suppliers who have expertise in plastic materials. They can provide valuable insights and recommendations based on their experience and knowledge of specific applications. Their input can help ensure the optimal material selection for the intended use.

7. Perform Prototype and Testing: Before finalizing the material selection, it’s advisable to produce prototypes or conduct testing using the chosen plastic material. This allows for verification of the material’s performance, dimensional accuracy, strength, durability, and other critical factors. Iterative testing and evaluation can help refine the material selection process if needed.

By following these steps and considering the application requirements, material properties, compatibility, manufacturing process, cost, and expert advice, it’s possible to choose the most appropriate plastic material for specific applications. Proper material selection is crucial for ensuring optimal performance, longevity, and safety in various industries and products.

What is the impact of temperature variations on plastic gears?

Temperature variations can have a significant impact on plastic gears. Here’s a detailed explanation of their effects:

1. Thermal Expansion: Plastic gears can experience thermal expansion or contraction with changes in temperature. Different types of plastics have varying coefficients of thermal expansion, meaning they expand or contract at different rates. This can result in dimensional changes, which may affect the gear’s meshing, clearance, and overall performance. It’s important to consider the thermal expansion characteristics of the specific plastic material used in the gear design.

2. Material Softening or Hardening: Plastic materials can exhibit changes in mechanical properties with temperature variations. In general, as temperature increases, plastic materials tend to soften and become more flexible, while at lower temperatures, they can become stiffer and more brittle. These changes can impact the gear’s load-bearing capacity, wear resistance, and overall durability. It’s crucial to select plastic materials that can maintain their mechanical integrity within the expected temperature range of the application.

3. Dimensional Stability: Plastic gears may experience dimensional changes or warping due to temperature fluctuations. Higher temperatures can cause plastic materials to deform, leading to misalignment, increased backlash, or reduced gear accuracy. Conversely, lower temperatures can cause contraction, resulting in tight clearances, increased friction, or gear binding. Proper design considerations, including material selection and gear geometry, can help mitigate the impact of temperature-induced dimensional changes.

4. Lubrication and Wear: Temperature variations can affect the lubrication properties of plastic gears. Higher temperatures can cause lubricants to degrade or become less effective, leading to increased friction, wear, and potential gear failure. Similarly, low temperatures can cause lubricants to thicken or solidify, hindering proper lubrication and increasing wear. Selecting lubricants suitable for the anticipated temperature range and periodic maintenance can help ensure proper lubrication and minimize wear on plastic gears.

5. Cold Flow and Creep: Some plastic materials, especially those with lower glass transition temperatures, may exhibit cold flow or creep at elevated temperatures. Cold flow refers to the gradual deformation or flow of plastic material under constant stress, while creep refers to the time-dependent deformation under a constant load. These phenomena can cause changes in gear geometry, tooth profile, or tooth engagement over time, potentially affecting gear performance and functionality. Understanding the material’s creep and cold flow characteristics is important when selecting plastic gears for applications exposed to temperature variations.

6. Impact on Lubricants and Seals: Temperature variations can also impact the performance of lubricants and seals used in gear systems. Extreme temperatures can cause lubricants to break down, lose viscosity, or leak from the gear assembly. Seals and gaskets may also be affected, leading to compromised gear housing integrity or increased friction. It’s crucial to consider temperature compatibility and select appropriate lubricants and seals that can withstand the anticipated temperature range.

In summary, temperature variations can significantly impact plastic gears by causing thermal expansion, material softening or hardening, dimensional changes, lubrication issues, cold flow or creep, and effects on lubricants and seals. Proper material selection, design considerations, and understanding the anticipated temperature range are essential to ensure the reliable and optimal performance of plastic gears in various applications.

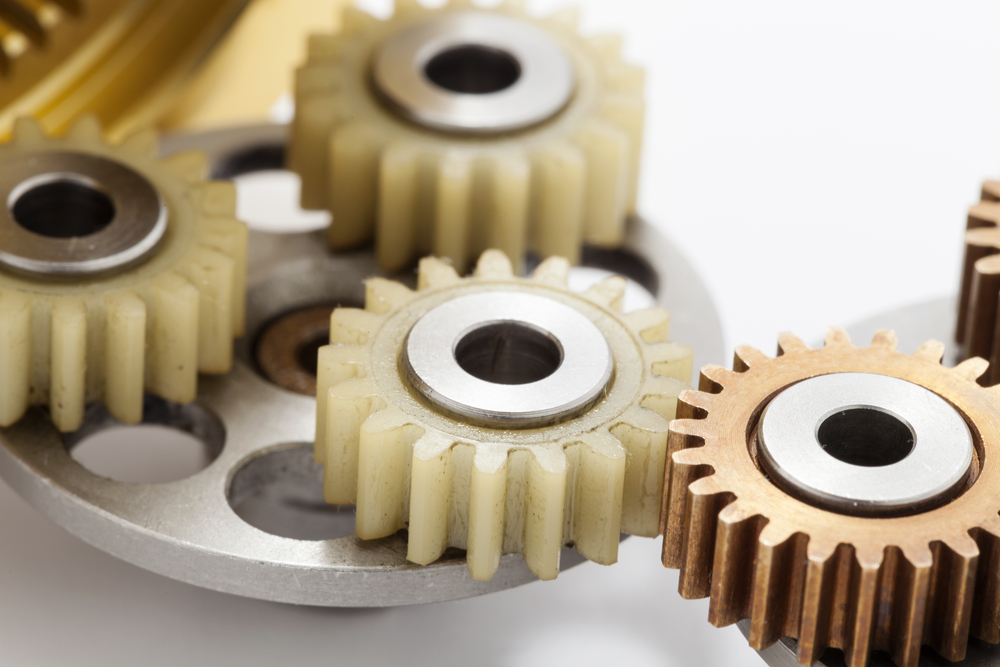

How do plastic gears differ from metal gears in terms of performance?

Plastic gears and metal gears exhibit differences in performance characteristics. Here’s a detailed explanation of how plastic gears differ from metal gears:

Strength and Durability:

- Metal gears are generally stronger and more durable compared to plastic gears. They can withstand higher torque, heavy loads, and harsh operating conditions. Metal gears are commonly used in applications that require high strength and durability, such as heavy machinery, automotive transmissions, and industrial equipment.

- Plastic gears have lower strength and may not be suitable for applications with high torque or heavy loads. However, advancements in plastic materials and manufacturing techniques have resulted in the development of high-performance plastics that offer improved strength and durability, allowing plastic gears to be used in a wider range of applications.

Weight:

- Plastic gears are significantly lighter in weight compared to metal gears. This lightweight characteristic is advantageous in applications where weight reduction is important, as it can contribute to energy efficiency, lower inertia, and reduced wear on supporting components.

- Metal gears are heavier due to the density and strength of the metal materials used. While the weight of metal gears can provide benefits in certain applications that require high inertia or increased stability, it may also result in additional energy consumption and higher stresses on supporting structures.

Noise and Vibration:

- Plastic gears have inherent damping properties that help reduce noise and vibration levels during operation. This makes them suitable for applications where noise reduction is desired, such as in consumer electronics or office equipment.

- Metal gears tend to generate more noise and vibration due to their higher stiffness. While there are methods to reduce noise in metal gears through design modifications and the use of noise-dampening materials, plastic gears generally offer better inherent noise and vibration reduction.

Wear and Lubrication:

- Plastic gears have the advantage of self-lubrication due to certain plastic materials having inherent lubricating properties. This reduces friction and wear between gear teeth, eliminating the need for external lubrication and simplifying maintenance requirements.

- Metal gears typically require lubrication to reduce friction and wear. Proper lubrication is essential for their performance and longevity. Insufficient or inadequate lubrication can lead to increased wear, heat generation, and even gear failure.

Corrosion Resistance:

- Plastic gears can exhibit excellent resistance to corrosion and chemicals, depending on the chosen plastic material. This makes them suitable for applications in corrosive environments where metal gears may suffer from degradation or require additional protective measures.

- Metal gears may corrode when exposed to moisture, chemicals, or certain operating environments. Corrosion can weaken the gears and compromise their performance and lifespan. However, corrosion-resistant metals or protective coatings can mitigate this issue.

Design Flexibility:

- Plastic gears offer greater design flexibility compared to metal gears. Plastic materials can be easily molded into complex shapes, allowing for the creation of custom gear profiles and tooth geometries. This design flexibility enables gear optimization for specific applications, improving performance, efficiency, and overall machinery design.

- Metal gears are more limited in terms of design flexibility due to the constraints of machining or shaping metal materials. While metal gears can still be customized to some extent, the process is generally more time-consuming and costly compared to plastic gear manufacturing.

It’s important to consider these performance differences when selecting between plastic and metal gears for a specific application. The requirements of the application, including load capacity, operating conditions, noise considerations, and durability expectations, should guide the choice of gear material.

editor by Dream 2024-04-22