Sprockets might be classified into typical sprockets, HK sprockets together with other sprockets.

one. Standard sprocket

Common sprockets are ANSI sprockets which can be engaged with conventional series roller chains. See P125 for dimensions.

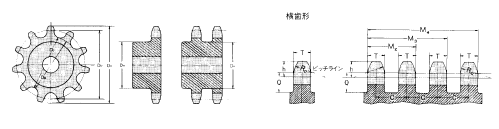

You will discover two sorts of tooth profiles: U-tooth and S-tooth.

2. HK sprocket

HK  sprockets is often engaged with HK series roller chains, and individuals for single strand chains are identical to conventional sprockets. However, sprockets for many strand chains are unique from common sprockets in sprocket tooth profile.

sprockets is often engaged with HK series roller chains, and individuals for single strand chains are identical to conventional sprockets. However, sprockets for many strand chains are unique from common sprockets in sprocket tooth profile.

3. Other sprockets

Other sprockets are intended according for the following calculation formulas to suit respective specialty chains.

The sprockets applied for your following chains will be the identical because the standard sprockets in tooth gap kind, but unique in tooth thickness (sprocket tooth profile).

four. Calculation of sprocket dimensions

The dimensions of conventional sprockets and various common sprockets are calculated as follows. To start with, the diameters of sprockets are calculated from the following calculation formulas.

Subsequent, sprocket tooth profile (the shape on the tooth dependant upon its thickness) is calculated through the following calculation formulas. (The values shown within the following pages had been calculated by these formulas and thought to be the common values.)

Calculation formulas for diameters and tooth gap forms Calculation formulas for diameters

Calculation of pitch diameter, tip diameter and caliper diameter

The fundamental dimensions of the sprocket suitable to get a chain pitch of 1 mm are respectively known as pitch diameter component, tip diameter factor and caliper diameter factor. The respective things for respective numbers of teeth are listed below. If these components are multiplied by chain pitch, the essential dimensions with the corresponding sprocket could be obtained.

Instance:

While in the situation of 80 (25.40 mm pitch) with 35 teeth Pitch diameter (Dp) = P×Pitch diameter factor

Calculation formulas for tooth gap varieties

Because the most rational tooth gap kinds during which the pressure angle improvements in response to your elongation of a smoothly rotated roller chain together with the lapse of support time, ANSI specify two kinds of tooth profiles: U-type and S-type. Normally, S-type tooth profiles are adopted in accordance with ANSI, and our typical sprockets also have S-tooth profiles.

Dimensions of Sprocket

Tags: