Many “gears” are utilized for automobiles, however they are also utilized for many various other machines. The most frequent one is the “transmitting” that conveys the power of engine to tires. There are broadly two roles the transmission of an automobile plays : one is certainly to decelerate the high rotation velocity emitted by the engine to transmit to tires; the other is to improve the reduction ratio in accordance with the acceleration / deceleration or driving speed of a car.

The rotation speed of an automobile’s engine in the overall state of generating amounts to 1 1,000 – 4,000 rotations per minute (17 – 67 per second). Since it is extremely hard to rotate tires with the same rotation quickness to perform, it is required to lessen the rotation speed using the ratio of the number of gear teeth. Such a role is named deceleration; the ratio of the rotation quickness of engine and that of tires is called the reduction ratio.

Then, exactly why is it necessary to alter the reduction ratio in accordance with the acceleration / deceleration or driving speed ? It is because substances require a large force to begin moving however they usually do not require such a big force to excersice once they have began to move. Automobile could be cited as an example. An engine, however, by its character can’t so finely change its output. Consequently, one adjusts its result by changing the decrease ratio utilizing a transmission.

The transmission of motive power through gears very much resembles the principle of leverage (a lever). The ratio of the number of teeth of gears meshing with each other  can be deemed as the ratio of the length of levers’ arms. That’s, if the reduction ratio is huge and the rotation quickness as output is lower in comparison to that as input, the power output by transmission (torque) will be huge; if the rotation quickness as output isn’t so low in comparison to that as input, however, the power output by transmission (torque) will be small. Thus, to improve the reduction ratio utilizing transmission is much akin to the basic principle of moving things.

can be deemed as the ratio of the length of levers’ arms. That’s, if the reduction ratio is huge and the rotation quickness as output is lower in comparison to that as input, the power output by transmission (torque) will be huge; if the rotation quickness as output isn’t so low in comparison to that as input, however, the power output by transmission (torque) will be small. Thus, to improve the reduction ratio utilizing transmission is much akin to the basic principle of moving things.

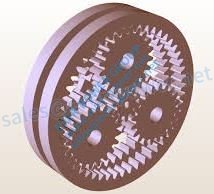

Then, how does a transmitting alter the reduction ratio ? The answer lies in the system called a planetary gear mechanism.

A planetary gear system is a gear mechanism comprising 4 components, namely, sun gear A, several planet gears B, internal gear C and carrier D that connects world gears as seen in the graph below. It includes a very complex structure rendering its style or production most challenging; it can understand the high decrease ratio through gears, however, it is a mechanism suitable for a reduction system that requires both little size and high performance such as transmission for automobiles.

In a planetary gearbox, many teeth are involved at once, that allows high speed reduction to be performed with fairly small gears and lower inertia reflected back again to the electric motor. Having multiple teeth discuss the load also enables planetary gears to transmit high degrees of torque. The mixture of compact size, huge speed reduction and high torque transmission makes planetary gearboxes a popular choice for space-constrained applications.

But planetary gearboxes perform have some disadvantages. Their complexity in design and manufacturing tends to make them a far more expensive option than additional gearbox types. And precision production is extremely important for these gearboxes. If one planetary gear is put closer to the sun gear than the others, imbalances in the planetary gears may appear, leading to premature wear and failure. Also, the small footprint of planetary gears makes temperature dissipation more difficult, so applications that operate at very high speed or experience continuous procedure may require cooling.

When utilizing a “standard” (i.e. inline) planetary gearbox, the motor and the powered equipment should be inline with one another, although manufacturers offer right-angle designs that include other gear sets (frequently bevel gears with helical tooth) to supply an offset between the input and output.

Input power (max)27 kW (36 hp)

Input speed (max)2800 rpm2

Output torque (intermittent)12,880 Nm(9,500 lb-ft)

Output torque (continuous)8,135 Nm (6,000 lb-ft)

1 Actual ratio would depend on the drive configuration.

2 Max input speed linked to ratio and max result speed

3 Max radial load positioned at optimum load position

4 Weight varies with configuration and ratio selected

5 Requires tapered roller planet bearings (unavailable with all ratios)

Approximate dry weight100 -181 kg (220 – 400 lb)4

Radial load (max)14,287kg (31,500 lb)3

Drive typeSpeed reducer

Hydraulic electric motor input SAE C or D hydraulic

Precision Planetary Reducers

This standard selection of Precision Planetary Reducers are perfect for use in applications that demand high performance, precise positioning and repeatability. These were specifically developed for make use of with state-of-the-art servo electric motor technology, providing tight integration of the engine to the unit. Design features include installation any servo motors, standard low backlash, high torsional stiffness, 95 to 97% efficiency and calm running.

They can be purchased in nine sizes with reduction ratios from 3:1 to 600:1 and output torque capacities up to 16,227 lb.ft. The output can be provided with a good shaft or ISO 9409-1 flange, for installation to rotary or indexing planetary gear reduction tables, pinion gears, pulleys or other drive components with no need for a coupling. For high precision applications, backlash amounts down to 1 arc-minute can be found. Right-angle and insight shaft versions of the reducers are also obtainable.

Standard applications for these reducers include precision rotary axis drives, traveling gantries & columns, materials handling axis drives and digital line shafting. Industries offered include Material Handling, Automation, Aerospace, Machine Tool and Robotics.

Unit Design &

Construction

Gearing: Featuring case-hardened & surface gearing with minimal put on, low backlash and low noise, making them the most accurate and efficient planetaries offered. Standard planetary style has three world gears, with an increased torque edition using four planets also offered, please see the Reducers with Result Flange chart on the machine Ratings tab under the “+” unit sizes.

Bearings: Optional output bearing configurations for app specific radial load, axial load and tilting instant reinforcement. Oversized tapered roller bearings are regular for the ISO Flanged Reducers.

Housing: Single piece steel housing with integral band gear provides higher concentricity and remove speed fluctuations. The casing can be installed with a ventilation module to improve insight speeds and lower operational temperature ranges.

Result: Available in a solid shaft with optional keyway or an ISO 9409-1 flanged interface. You can expect an array of standard pinions to mount directly to the output style of your choice.

Unit Selection

These reducers are usually selected predicated on the peak cycle forces, which usually happen during accelerations and decelerations. These cycle forces depend on the powered load, the rate vs. time profile for the cycle, and any other exterior forces acting on the axis.

For application & selection assistance, please call, fax or email us. Your application info will be reviewed by our engineers, who will recommend the very best solution for the application.

Ever-Power Automation’s Gearbox products offer high precision at affordable prices! The Planetary Gearbox item offering contains both In-Line and Right-Position configurations, built with the design goal of supplying a cost-effective gearbox, without sacrificing quality. These Planetary Gearboxes can be found in sizes from 40mm to 180mm, well suited for motors which range from NEMA 17 to NEMA 42 and bigger. The Spur Gearbox series offers an efficient, cost-effective choice compatible with Ever-Power Automation’s AC Induction Gear Motors. Ever-Power Automation’s Gearboxes are offered in up to 30 different gear ratios, with torque rankings up to 10,488 in-lbs (167,808 oz-in), and are appropriate for most Servo,

SureGear Planetary Gearboxes for Small Ever-Power Motors

The SureGear PGCN series is an excellent gearbox value for servo, stepper, and other movement control applications requiring a NEMA size input/output interface. It provides the best quality designed for the price point.

Features

Wide range of ratios (5, 10, 25, 50, and 100:1)

Low backlash of 30 arc-min or less

20,000 hour service life

Maintenance free; requires no additional lubrication

NEMA sizes 17, 23, and 34

Includes hardware for mounting to SureStep stepper motors

Optional shaft bushings designed for mounting to other motors

1-year warranty

Applications

Material handling

Pick and place

Automation

Packaging

Various other motion control applications requiring a Ever-Power input/output

Spur gears certainly are a type of cylindrical equipment, with shafts that are parallel and coplanar, and tooth that are directly and oriented parallel to the shafts. They’re arguably the simplest and most common type of gear – simple to manufacture and ideal for an array of applications.

One’s teeth of a spur gear ‘ve got an involute profile and mesh one particular tooth at the same time. The involute type means that spur gears simply generate radial forces (no axial forces), nevertheless the method of tooth meshing causes high pressure on the gear the teeth and high sound creation. Because of this, spur gears are often utilized for lower swiftness applications, although they can be utilized at almost every speed.

An involute equipment tooth includes a profile this is actually the involute of a circle, which means that since two gears mesh, they get in touch with at an individual point where in fact the involutes meet. This aspect movements along the tooth areas as the gears rotate, and the type of force ( referred to as the line of activities ) is tangent to both foundation circles. Therefore, the gears adhere to the fundamental regulation of gearing, which claims that the ratio of the gears’ angular velocities must stay continuous throughout the mesh.

Spur gears could be produced from metals such as steel or brass, or from plastics such as nylon or polycarbonate. Gears manufactured from plastic produce less sound, but at the difficulty of power and loading capacity. Unlike other gear types, spur gears don’t encounter high losses because of slippage, therefore they often have high transmission overall performance. Multiple spur gears can be utilized in series ( referred to as a gear teach ) to achieve large reduction ratios.

There are two primary types of spur gears: external and internal. Exterior gears have got the teeth that are cut externally surface of the cylinder. Two external gears mesh with one another and rotate in opposite directions. Internal gears, on the other hand, have teeth that are cut on the inside surface of the cylinder. An exterior gear sits within the internal equipment, and the gears rotate in the same direction. Because the shafts sit closer together, internal equipment assemblies are smaller sized than external equipment assemblies. Internal gears are primarily used for planetary gear drives.

Spur gears are usually viewed as best for applications that want speed reduction and torque multiplication, such as ball mills and crushing equipment. Types of high- velocity applications that use spur gears – despite their high noise amounts – include consumer devices such as washers and blenders. Even though noise limits the utilization of spur gears in passenger automobiles, they are generally found in aircraft engines, trains, and even bicycles.

planetary gear reduction

Tags: