Product Description

Customized High Precision CNC Machining Stainless Steel Alloy Steel Transmission Gear

Product Description

CHINAMFG provides one-stop solution service for your metallurgical equipment spare parts, currently we produce rolling mill rolls, guide, blades, gears, sprocket wheels, worm, worm gears, flange processing parts, welding processing parts and etc.

Rolls do the most important work in a rolling mill. They constitute a very important component of the running cost of the rolling mill. Hence, it is necessary that optimum performance is obtained from the rolls. Rolls come in a wide variety of sizes, the smallest roll weighs only a few kilograms, the heaviest around 250 tons a piece, and the variety of grades used is also wide, from ductile iron (spheroidal graphite iron) to tungsten carbide, covering all kinds of tool steels and special steels, used only for rolls. Roll properties include blend of hardness and strength as well as resistance to thermal cracking, shock loading, and wear.

| Product Name | Conveyor Pulley |

| Size | Customized |

| Color | Customized |

| Technology | Forging |

| Surface Treament | Paint Spraying, Grind Machining, Heat Treatment |

| Material | Alloy steel, Carbon steel, Carburizing steel, Quenched and Tempered steel |

| Inspection | Chemical Composition Test, Ultrasonic Test, Penetration Test, Radiographic Test, Magnetic Test, Tensile Strength Test, Impact Test, Hardness Test, Dimension Test |

| Payment | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Lead Time | 4 weeks |

Chemical Component

| C | Si | Mn | Cr | Ni | Mo | HS | Mpa |

| 0.50-0.60 | ≤0.40 | 0.50-0.80 | 0.50-0.80 | 1.40-1.80 | 0.15-0.30 | 55-58 | ≥1200 |

| 0.40-0.47 | 0.40-0.70 | 0.40-0.60 | 1.50-2.00 | 0.80-1.20 | 0.80-1.20 | 54-56 | ≥1200 |

| 0.32-0.42 | 0.80-1.20 | ≤0.40 | 4.50-5.50 | 1.60-2.40 | 2.00 | ||

| 0.35-0.45 | 0.80-1.20 | 0.25-0.70 | 3.00-3.75 |

Company Profile

HangZhou CHINAMFG Heavy Industry Technology Development Co., Ltd. is a leading enterprise in the wear-resistant casting of large engineering machinery and the forging of large equipment parts located in the New Material Industrial Park, Xihu (West Lake) Dis. High-Tech Zone, HangZhou City, the company covers an area of 90 Square kilometer and currently has more than 300 employees. The company is equipped with lost molding production line and lost casting production line imported from FATA Company in Italy, Inductotherm Vacuum Degassing Furnace(USA), Foseco Casting Technology(U.K), SPECTRO Spectrometer (Germany), the currently most advanced ZZ418A vertical parting flaskless shoot squeeze molding machine Disa production line, horizontal molding line and self-control lost casting production line in China, the most advanced sand treatment system in China. With 3 gas trolley heat treatment CHINAMFG and pusher-type CHINAMFG full-automatic heat treatment production lines, the company can annually produce 30,000 tons of various wear-resisting castings and metallurgical equipment forging parts.

Manufacturing Technique

Packing and Shipping

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided. After goods well packaged, we need only 1 day ship goods to ZheJiang port, which means that most of the spare parts you bought from Hyton, it will get your port within 45 days all around the world if shipment by sea.

Our Advantages

1)Your inquiry related to our product & price will be rapidly.

2) Well trained & experienced staff are to answer all your inquiries in English of course.

3) Your business relationship with us will be confidential to any third party.

4) One stop purchase service: extensive rang of products for qualified offering.

5) We response to client’s inquiry within 12 hours.

FAQ

1.Q: What kind of products do you make?

A: We specialize in metallurgical equipment casting and forging parts, such as forging rolls, guide, blades, gears, sprocket wheels, worm, worm gears, flange processing parts, welding processing parts and etc.

2.Q: What kind of material do you offer?

A: High manganese steel, high chrome iron, alloy steel, low carbon steel, medium carbon steel, Stainless Steel and etc.

3.Q: What is your time of delivery?

A: Our lead time is generally 2-4 weeks for casting parts and shipping time is about 2-4 weeks.

4.Q: How to test your quality?

A: We will show you material inspection and measurement inspection after fininsh the goods, at the same time, we will give you the life time guarantee letter after shipping the goods. The best suggestion to all the customer who may interest our product-Test 2 set first, all the good business relationship all from test and trust.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Gear Position: | External Gear |

| Manufacturing Method: | Forging |

| Toothed Portion Shape: | Bevel Wheel |

| Material: | Cast Steel |

| Type: | Circular Gear |

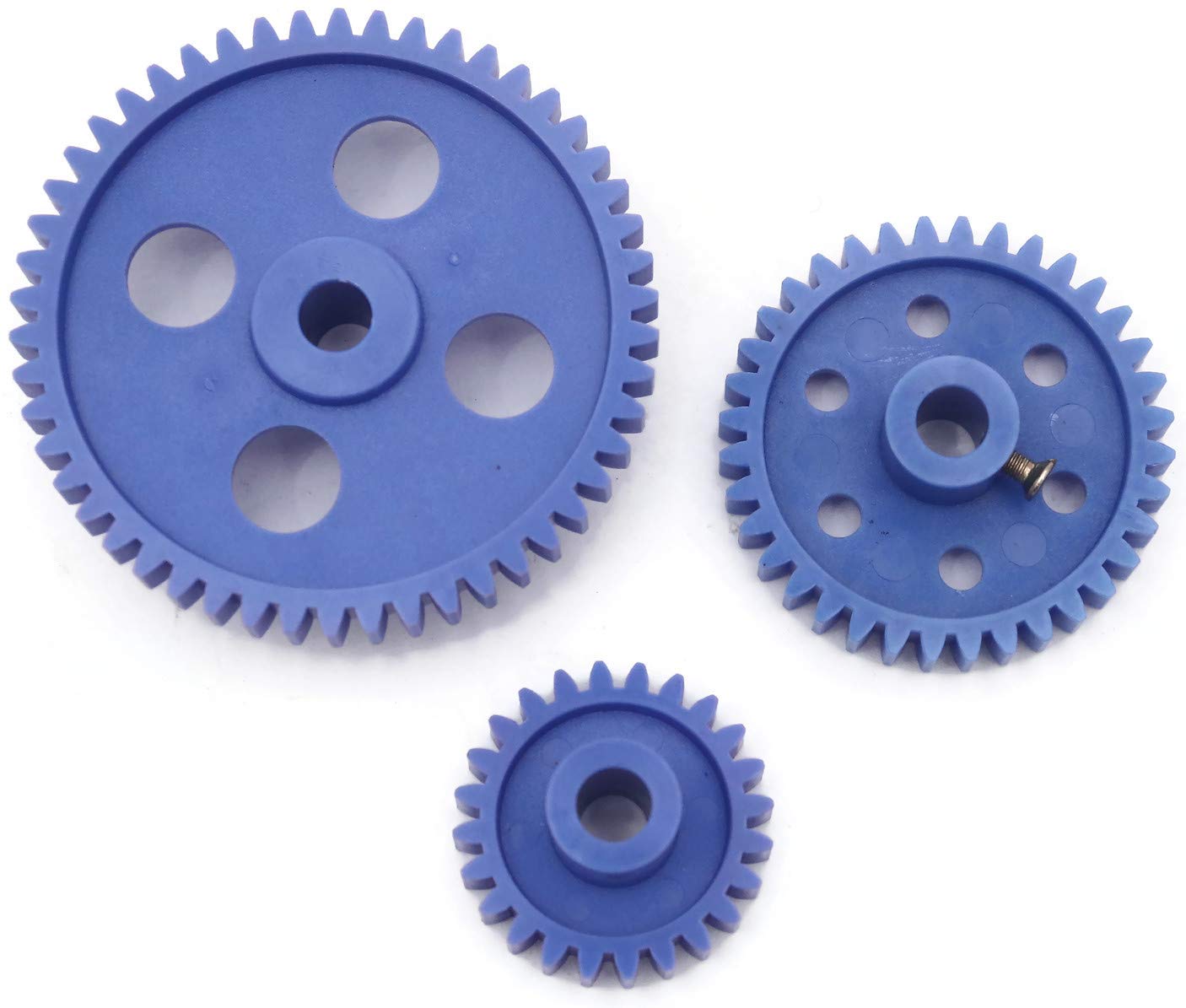

Can plastic gears withstand high torque and load conditions?

Plastic gears have certain limitations when it comes to withstanding high torque and load conditions. Here’s a detailed explanation of their capabilities:

Plastic gears can be designed and manufactured to handle a range of torque and load conditions, but their performance is generally inferior to that of metal gears in high-stress applications. The specific capabilities of plastic gears depend on various factors, including the chosen plastic material, gear design, tooth profile, and operating conditions.

While plastic gears may not be suitable for extremely high torque or heavy-load applications, they can still provide reliable performance in many moderate-load scenarios. Plastic gears are commonly used in applications with light to moderate loads, where their unique properties and advantages outweigh their limitations.

Some plastic materials, such as acetal (POM) and polyamide (nylon), offer good strength and wear resistance, allowing them to handle moderate torque and load conditions. These materials can be reinforced with additives or fillers to enhance their mechanical properties and increase their load-bearing capacity.

It’s important to note that when designing with plastic gears, engineers must carefully consider factors such as gear size, tooth geometry, material selection, and operating conditions. Reinforcement techniques, such as using metal inserts or reinforcing fibers, may be employed to improve the strength and load-bearing capabilities of plastic gears in certain applications.

In high torque or heavy-load applications, metal gears, particularly those made from steel or other high-strength alloys, are generally preferred due to their superior strength and durability. Metal gears offer higher load capacities, better resistance to deformation, and increased resistance to wear under extreme conditions.

Ultimately, the suitability of plastic gears for high torque and load conditions depends on the specific requirements of the application and the trade-off between the benefits of plastic gears, such as weight reduction and noise reduction, and the higher load-bearing capabilities of metal gears.

It’s recommended to consult with gear manufacturers or mechanical engineers to determine the most appropriate gear material and design for a particular application, especially when high torque and load conditions are expected.

How do plastic gears handle lubrication and wear?

Plastic gears handle lubrication and wear differently compared to metal gears. Here’s a detailed explanation of their behavior:

1. Lubrication in Plastic Gears: Lubrication plays a crucial role in the performance and longevity of plastic gears. While metal gears often require continuous lubrication, plastic gears have different lubrication requirements due to their inherent properties. Here are some key considerations:

- Self-Lubrication: Some plastic materials, such as certain formulations of polyoxymethylene (POM), have inherent self-lubricating properties. These materials have a low coefficient of friction and can operate with minimal lubrication or even dry. Self-lubricating plastic gears can be advantageous in applications where the use of external lubricants is impractical or undesirable.

- Lubricant Compatibility: When external lubrication is necessary, it’s important to choose lubricants that are compatible with the specific plastic material used in the gears. Certain lubricants may degrade or adversely affect the mechanical properties of certain plastics. Consultation with lubricant manufacturers or experts can help identify suitable lubricants that won’t cause degradation or wear issues.

- Reduced Lubricant Requirements: Plastic gears generally have lower friction coefficients compared to metal gears. This reduced friction results in lower heat generation and less wear, which in turn reduces the demand for lubrication. Plastic gears may require less frequent lubricant replenishment or lower lubricant volumes, reducing maintenance requirements.

- Appropriate Lubricant Application: When applying lubricant to plastic gears, care should be taken to avoid excessive amounts that could lead to contamination or leakage. Lubricants should be applied in a controlled manner, ensuring they reach the critical contact points without excessive buildup or excess spreading beyond the gear surfaces.

2. Wear in Plastic Gears: Plastic gears exhibit different wear characteristics compared to metal gears. While metal gears typically experience gradual wear due to surface interactions, plastic gears may undergo different types of wear mechanisms, including:

- Adhesive Wear: Adhesive wear can occur in plastic gears when high loads or speeds cause localized melting or deformation at the gear teeth contact points. This can result in material transfer between gear surfaces and increased wear. Proper material selection, gear design optimization, and lubrication can help minimize adhesive wear in plastic gears.

- Abrasive Wear: Abrasive wear in plastic gears can be caused by the presence of abrasive particles or contaminants in the operating environment. These particles can act as abrasive agents, gradually wearing down the gear surfaces. Implementing effective filtration or sealing mechanisms, along with proper maintenance practices, can help reduce abrasive wear in plastic gears.

- Fatigue Wear: Plastic materials can exhibit fatigue wear under cyclic loading conditions. Repeated stress and deformation cycles can lead to crack initiation and propagation, ultimately resulting in gear failure. Proper gear design, material selection, and avoiding excessive loads or stress concentrations can help mitigate fatigue wear in plastic gears.

3. Gear Material Selection: The choice of plastic material for gears can significantly impact their lubrication and wear characteristics. Different plastic materials have varying coefficients of friction, wear resistance, and compatibility with lubricants. It’s important to select materials that offer suitable lubrication and wear properties for the specific application requirements.

4. Operational Considerations: Proper operating conditions and practices can also contribute to the effective handling of lubrication and wear in plastic gears. Avoiding excessive loads, controlling operating temperatures within the material’s limits, implementing effective maintenance procedures, and monitoring gear performance are essential for ensuring optimal gear operation and minimizing wear.

In summary, plastic gears can handle lubrication and wear differently compared to metal gears. They may exhibit self-lubricating properties, reduced lubricant requirements, and require careful consideration of lubricant compatibility. Plastic gears can experience different types of wear, including adhesive wear, abrasive wear, and fatigue wear. Proper material selection, gear design, lubrication practices, and operational considerations are crucial for ensuring efficient lubrication and minimizing wear in plastic gears.

How do plastic gears differ from metal gears in terms of performance?

Plastic gears and metal gears exhibit differences in performance characteristics. Here’s a detailed explanation of how plastic gears differ from metal gears:

Strength and Durability:

- Metal gears are generally stronger and more durable compared to plastic gears. They can withstand higher torque, heavy loads, and harsh operating conditions. Metal gears are commonly used in applications that require high strength and durability, such as heavy machinery, automotive transmissions, and industrial equipment.

- Plastic gears have lower strength and may not be suitable for applications with high torque or heavy loads. However, advancements in plastic materials and manufacturing techniques have resulted in the development of high-performance plastics that offer improved strength and durability, allowing plastic gears to be used in a wider range of applications.

Weight:

- Plastic gears are significantly lighter in weight compared to metal gears. This lightweight characteristic is advantageous in applications where weight reduction is important, as it can contribute to energy efficiency, lower inertia, and reduced wear on supporting components.

- Metal gears are heavier due to the density and strength of the metal materials used. While the weight of metal gears can provide benefits in certain applications that require high inertia or increased stability, it may also result in additional energy consumption and higher stresses on supporting structures.

Noise and Vibration:

- Plastic gears have inherent damping properties that help reduce noise and vibration levels during operation. This makes them suitable for applications where noise reduction is desired, such as in consumer electronics or office equipment.

- Metal gears tend to generate more noise and vibration due to their higher stiffness. While there are methods to reduce noise in metal gears through design modifications and the use of noise-dampening materials, plastic gears generally offer better inherent noise and vibration reduction.

Wear and Lubrication:

- Plastic gears have the advantage of self-lubrication due to certain plastic materials having inherent lubricating properties. This reduces friction and wear between gear teeth, eliminating the need for external lubrication and simplifying maintenance requirements.

- Metal gears typically require lubrication to reduce friction and wear. Proper lubrication is essential for their performance and longevity. Insufficient or inadequate lubrication can lead to increased wear, heat generation, and even gear failure.

Corrosion Resistance:

- Plastic gears can exhibit excellent resistance to corrosion and chemicals, depending on the chosen plastic material. This makes them suitable for applications in corrosive environments where metal gears may suffer from degradation or require additional protective measures.

- Metal gears may corrode when exposed to moisture, chemicals, or certain operating environments. Corrosion can weaken the gears and compromise their performance and lifespan. However, corrosion-resistant metals or protective coatings can mitigate this issue.

Design Flexibility:

- Plastic gears offer greater design flexibility compared to metal gears. Plastic materials can be easily molded into complex shapes, allowing for the creation of custom gear profiles and tooth geometries. This design flexibility enables gear optimization for specific applications, improving performance, efficiency, and overall machinery design.

- Metal gears are more limited in terms of design flexibility due to the constraints of machining or shaping metal materials. While metal gears can still be customized to some extent, the process is generally more time-consuming and costly compared to plastic gear manufacturing.

It’s important to consider these performance differences when selecting between plastic and metal gears for a specific application. The requirements of the application, including load capacity, operating conditions, noise considerations, and durability expectations, should guide the choice of gear material.

editor by CX 2023-12-25